Ⅰ.Operating Condition Compatibility and Core Risk Analysis

Your operating conditions: Corrosive wastewater containing carbon-sulfur gas (pH 5-9), flow rate 50 m³/h, head 40 m, 60Hz power supply. The core risks are "cavitation caused by gas-containing medium" and "damage to seals/lining caused by corrosive medium". The fluoroplastic lining of the IHF pump is suitable for the corrosive environment with pH 5-9, but the following issues must be focused on:

Ⅱ.Operation Restrictions: Non-Negotiable Red Lines

- Prohibition of idling: Under no circumstances should the pump be started when there is no medium inside (idling will instantly burn out the bearings and wear the lining).

- Flow rate restriction: The long-term operating flow rate must be ≥ 30% of the rated flow rate (the rated flow rate of this pump at 60Hz needs to be confirmed; assuming it is Qₙ, the operating flow rate should be ≥ 0.3Qₙ). This prevents local cavitation of the impeller caused by low flow rates. Additionally, the pump must not operate with the valve fully open.

- Cavitation phenomenon

- If "sudden rise in medium temperature, sudden increase in vibration, or drop in head" occurs, shut down the pump immediately (gas-containing medium is more likely to cause cavitation, and vigilance is required even with a booster device).

- The gas content in the medium must be ≤ 5% (if it exceeds the standard, degassing must be performed first; otherwise, cavitation cannot be avoided even with boosting).

- Temperature control: The temperature change rate of the medium must be ≤ 40℃ per cycle (rapid cooling or heating will affect the fluorinated lining).

Ⅲ.Pre-Start Preparation: "Gas Discharge Battle" for Gas-Containing Medium

- Liquid filling and gas discharge: Eliminate air bubbles

- Close the outlet valve → Open the inlet valve and the pump body vent valve → Fill the pump cavity with medium until the vent valve discharges continuous, bubble-free liquid (gas-containing medium is prone to residual air bubbles; repeated gas discharge is required, and tapping the pump body gently can assist in bubble removal).

- Confirm that the pipeline booster device has been started and the inlet pressure is stable (inlet pressure ≥ 0.2MPa is recommended).

- Rotation direction check: Operate in the indicated direction

- Jog the motor (momentary power-on) and check if the shaft rotation direction is consistent with the arrow on the pump body (the rotation speed at 60Hz is 3600rpm; incorrect rotation direction may cause the impeller to fall off!).

- Valves and flow paths: Start-up protection

- Fully open the inlet valve and fully close the outlet valve (reduce motor

- load during start-up; the starting current at 60Hz is higher, so overload must be avoided).

Ⅳ.Start-Up and Test Operation: 5 Steps to Ensure Safety

- Start the motor: Observe the operating sound (should be stable, no sharp noise), and touch the bearing housing with your hand (no obvious overheating).

- Test operation for 5-10 minutes:

- Monitor vibration: ≤ 85dB (A) (a mobile phone APP can be used for preliminary testing; if abnormal, shut down the pump to check impeller balance).

- Bearing temperature: ≤ Ambient temperature + 40℃; Motor temperature: ≤ 90℃ (Class B insulation).

- Slowly open the outlet valve: Adjust the flow rate to 50 m³/h (prioritize coarse adjustment with the outlet valve and fine adjustment with frequency conversion; frequent valve opening/closing is prohibited to prevent seal leakage).

- Parameter verification:

- Check if the inlet/outlet pressure matches the head (40m ≈ 0.4MPa; pipeline losses must be ≤ the design pressure of 2.0MPa).

- Motor current: ≤ Rated value (for an 11kW motor, the rated current at 60Hz needs to be confirmed; if overcurrent occurs, reduce the load immediately).

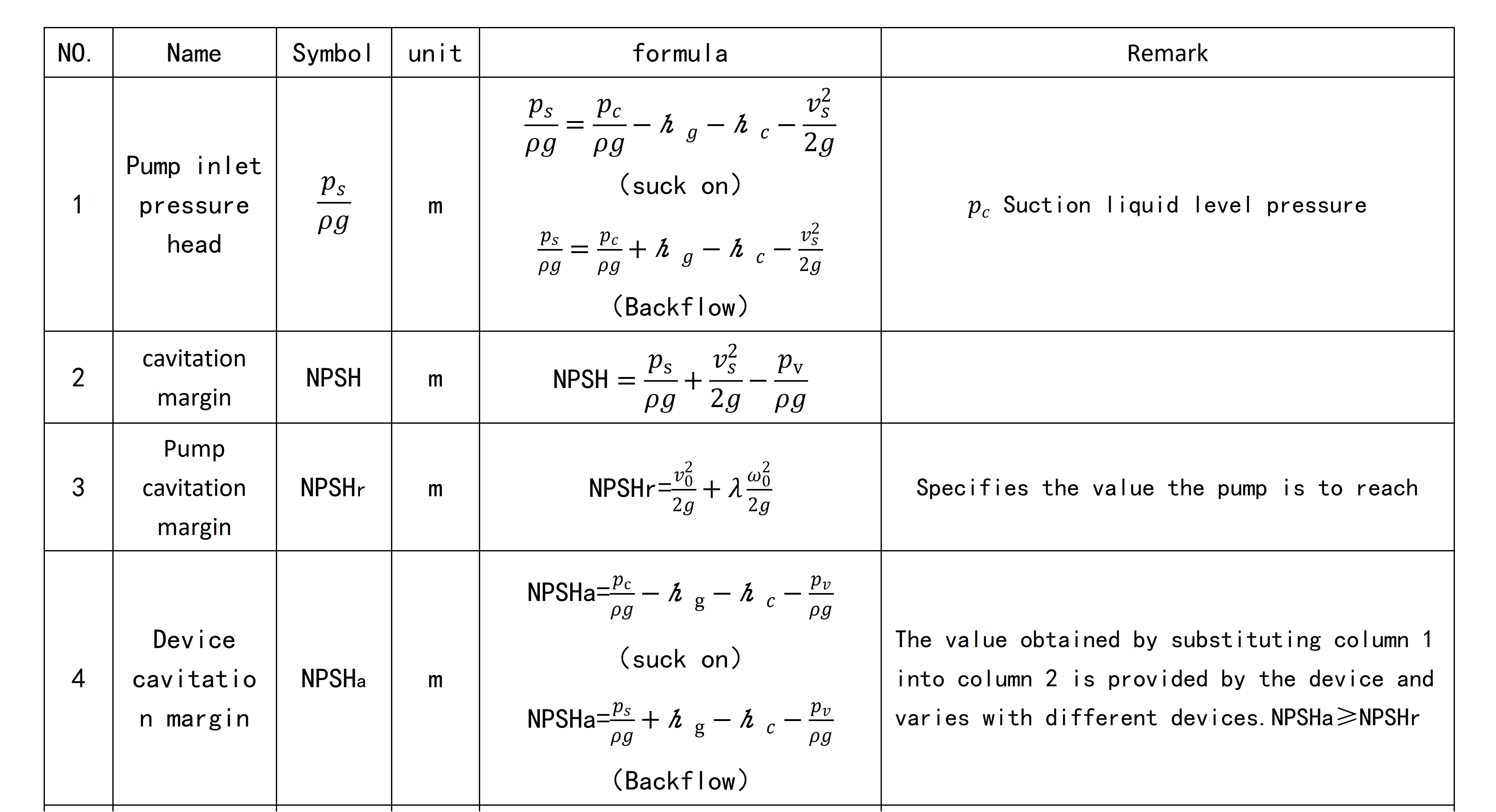

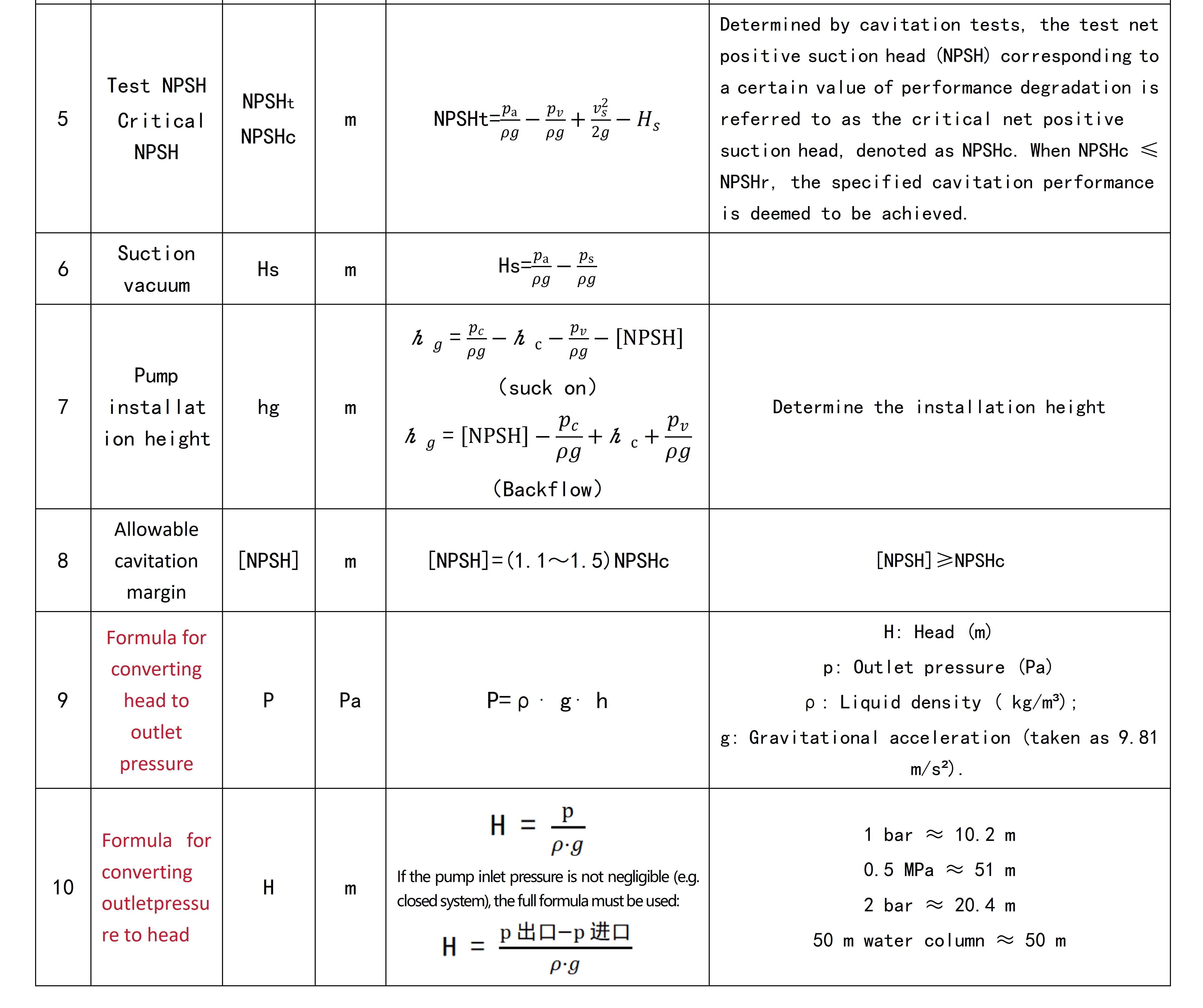

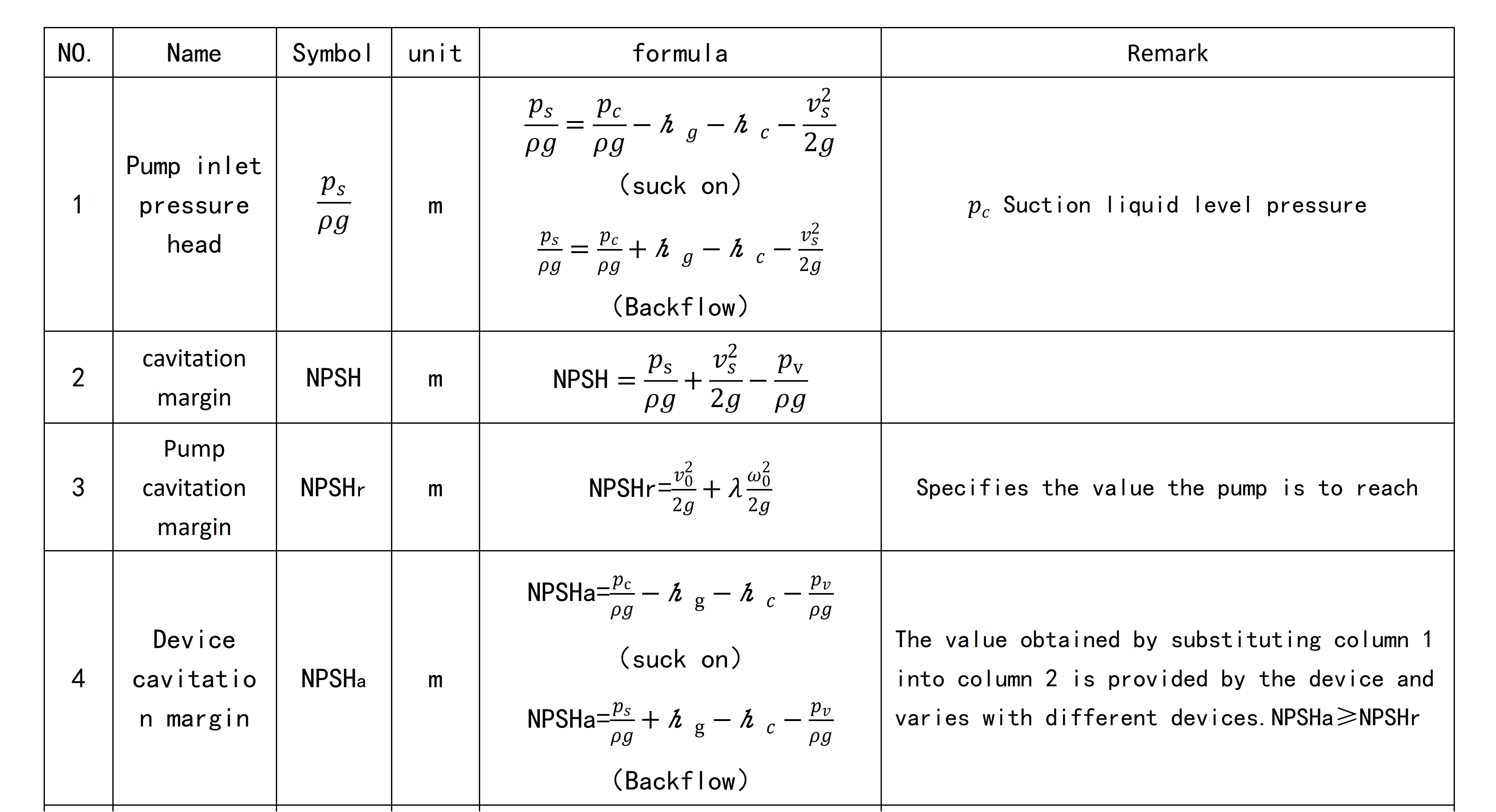

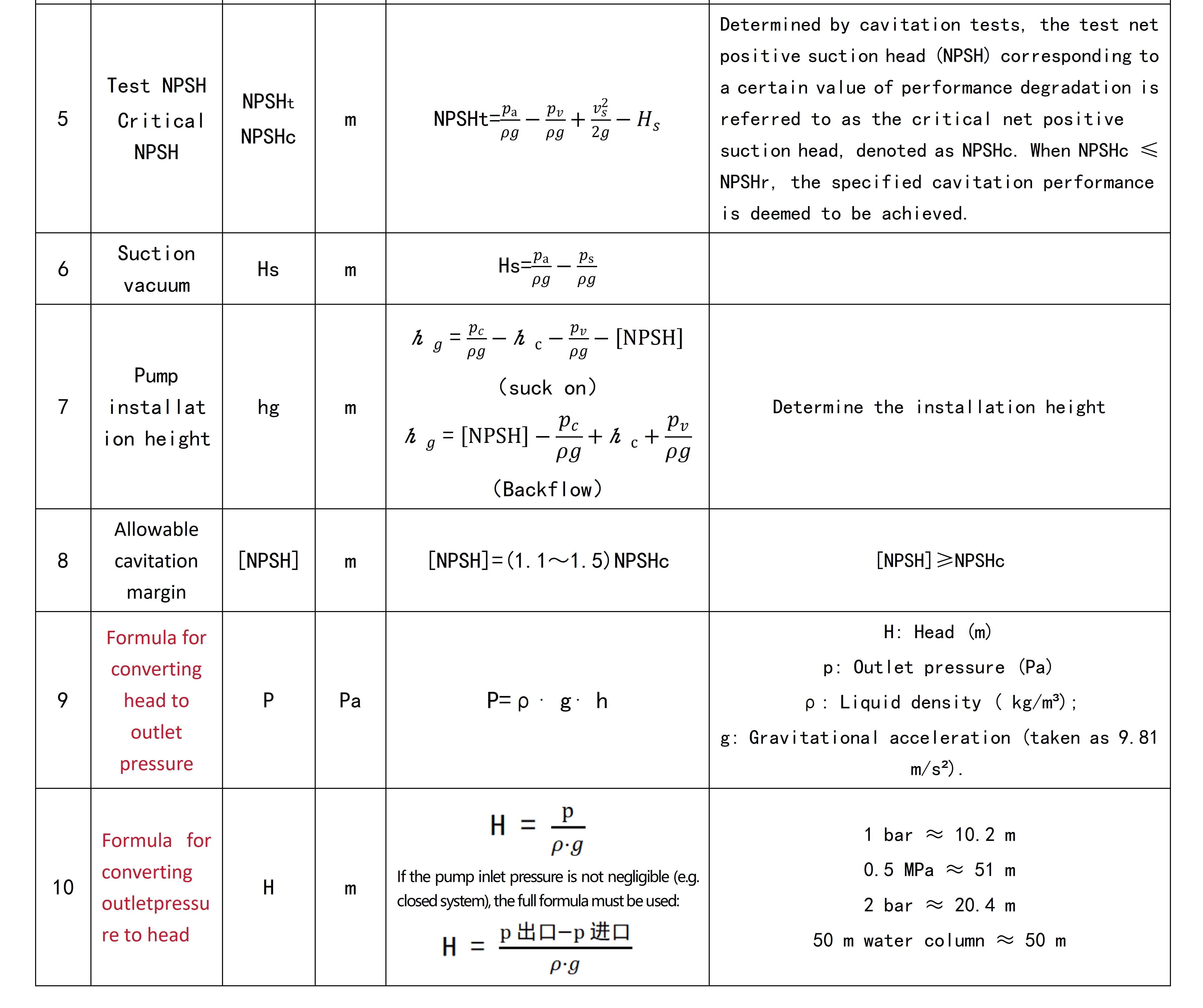

Common formulas are shown in the figure below

Ⅴ.Operation Monitoring: Dual Protection Against Gas Contamination and Corrosion

- Cavitation early warning (most critical):

- Signals: Sudden increase in vibration, sharp noise ("sizzling" sound), or head drop of more than 5%.

- Action: Throttle down the outlet valve → Check the booster device → Detect the gas content in the medium → If ineffective, shut down the pump to drain the liquid and refill the pump.

- Corrosion protection (seal is the key):

- Check seal leakage every hour: ≤ 5 drops per minute is normal; if exceeding the limit, mark it immediately (corrosive medium will accelerate leakage, so the seal must be replaced promptly; silicon carbide vs. silicon carbide material is recommended).

- Parameter stability control:

- Flow rate: 50 ± 5% m³/h (if the flow rate is lower than 30% of the rated flow rate for a long time, impeller protection measures must be taken).

- Head: 40 ± 5% (if lower than the standard, check the inlet pressure, pipeline blockage, or impeller wear).。

Ⅵ.Shutdown and Storage: Anti-Corrosion and Anti-Freezing

- Normal shutdown:

- Close the outlet valve → Cut off the power supply → Close the inlet valve → Open the vent valve to drain all medium from the pump cavity (residual corrosive liquid = accelerated damage).

- Long-term shutdown (> 1 week):

- Disassemble the seal → Rinse the pump cavity with clean water → Seal the inlet and outlet after drying (the lining is susceptible to corrosion from accumulated water).

Ⅶ.Special Reminder for 60Hz: Changes Caused by Rotation Speed

1.Performance deviation: The rotation speed at 60Hz is 20% higher than that at 50Hz, resulting in a 20% increase in flow rate, 44% increase in head, and 73% increase in power (the 60Hz curve provided by the pump manufacturer shall prevail to ensure that 50 m³/h and 40 m are within the high-efficiency zone and the motor power does not exceed 11kW).

2.Vibration sensitivity: At high rotation speeds, the dynamic balance of the impeller is more critical. If vibration is abnormal, first check whether the impeller is loose or worn.

Ⅷ.Emergency Plan: Rapid Response to Ensure Safety

|

Fault

|

Signal

|

First-Action Response

|

|

Sudden

Cavitation

|

Sudden increase in

vibration/noise

|

Immediately throttle down the outlet valve and start the standby booster pump

|

|

Massive Seal Leakage

|

Dripping liquid in a continuous stream

|

Shut down the pump immediately and replace the seal with protective equipment

|

|

Motor Overheating

|

Temperature ≥ 90℃

|

Throttle down the outlet valve to reduce the load; if overheating persists, shut down the pump

|

Recommendation: Develop a Daily Inspection Checklist to record data such as flow rate, pressure, vibration, and leakage, and compare trends weekly (cavitation in gas-containing medium will deteriorate gradually; early detection and treatment are essential). For any questions about the pump, feel free to contact us!

Wish your pump operates smoothly. For any detailed questions, please do not hesitate to communicate!

Anhui Freida Pump Valve Manufacturing Technology Co., Ltd.

Corporate Email: [email protected]

WhatsApp: +8617729930222

English

English русский

русский Español

Español Français

Français