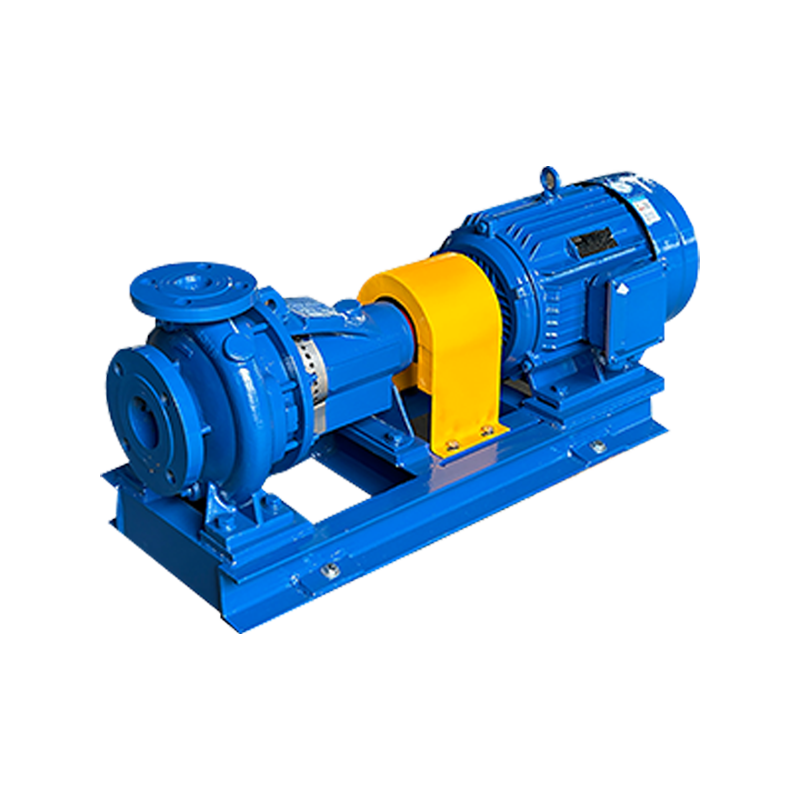

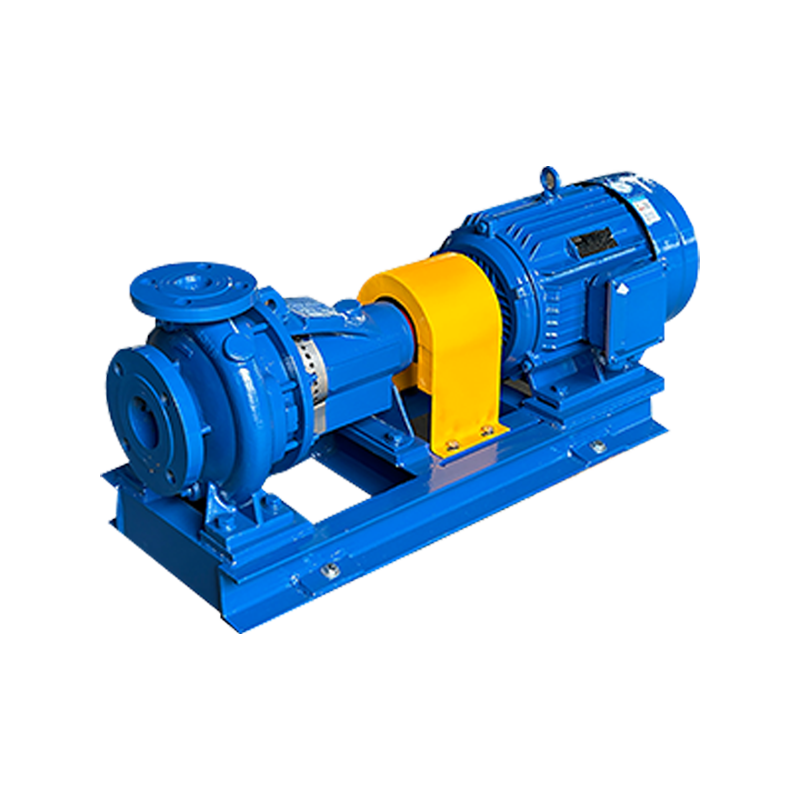

When it comes to industrial fluid handling, the metal centrifugal pump is a highly efficient and versatile solution. Whether you're dealing with clean water, chemical mixtures, or abrasive liquids, these industrial pumps deliver consistent performance across a wide range of applications.

A centrifugal pump functions by using a rotating impeller to create velocity, which is then converted into flow. This process enables rapid and efficient fluid transfer, which is critical in sectors such as agriculture, manufacturing, petrochemical processing, and municipal water systems. Choosing a metallic pump for this task provides added durability and corrosion resistance, especially when exposed to harsh or reactive fluids.

The material composition of a metal centrifugal pump—typically stainless steel, bronze, or cast iron—ensures strength and longevity. These mechanical pumps can withstand mechanical stress, high temperatures, and aggressive chemicals far better than their plastic or polymer counterparts.

Another significant benefit of a metal centrifugal water pump is its ease of maintenance. Thanks to their simple design and accessible components, these pumps offer reduced downtime and lower repair costs. With proper upkeep, a quality industrial centrifugal pump can operate effectively for years without performance degradation.

Moreover, advancements in pump engineering have led to improvements in energy efficiency, reducing power consumption while maintaining high output. This makes the metal centrifugal pump not only a reliable choice but also an eco-friendly one.

From transferring water in irrigation systems to moving corrosive chemicals in refineries, metal centrifugal pumps are the backbone of many modern fluid systems. If your operation requires durability, consistency, and power, investing in a metallic centrifugal pump is a decision that pays off in the long run.

English

English русский

русский Español

Español Français

Français